Machine equipment

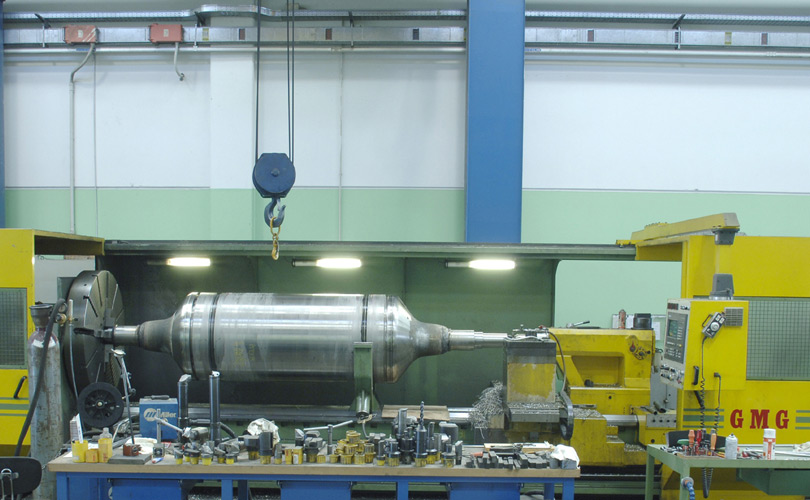

The Unigen Steel Engineering headquarters has about 5000 m² spread over three areas served by 4 bridge cranes weighing over 10 tonnes, one of which weighs 32 tonnes and one 50 tonnes. Our sizeable machine equipment allows us to work at the forefront of the national and international elite, serving important names of great industry. Our turning, milling, and boring machining and mechanical carpentry have made it possible for us to earn the trust of industries of primary importance.

Our numerically controlled machines can perform medium and large machining, up to fifty tonnes and ten meters in length. Specialized and technically prepared workers accurately follow every step of the machining cycle of every piece, which is then quality checked with a specific ZEISS machine.

Turning

- CNC turning with a complete motorized unit of a motorized boring and milling system and punching and boring for a maximum length of 4000 mm in turnable diameter and 1700 mm in maximum length 7000 mm SIEMENS 840D control system;

- CNC turning turnable diameter 1300 mm and 5000 mm in length;

- CNC turning 420 mm in length and 3000 mm with motorized unit for boring and milling SIEMENS 840D control unit;

- CNC turning 500 mm in length and 3000 mm with motorized unit for boring and milling SIEMENS 840D control unit;

- Visualised parallel turning turnable diameter 1200 mm and 4000 mm in length;

- Visualised parallel turning turnable diameter 1300 mm and 6000 mm in length.

Boring/Milling

- TOS milling machine fixed bench runs 8000 x 2000 x 1000 mm;

- Continuous spindle milling diameter 135 fixed upright runs X 3000 Y 2000 Z 1800 CNC FANUC control unit, tool change 60 table stations 1800 x 2000 mm;

- MAZAK MTV 655/80N vertical work centre with MAZATROL FUSION 640M ISO50 tool change control with 30 run stations X 2000 Y 650 Z 740;

- MAKE mobile upright milling runs X 10000 Y 3500 Ram exit 400 x 450 runs 1000 Spindle diameter 160 run 800, rotating table 2500 x 3000 run 1500, 40-tonnes capacity. 40-position automatic tool changer. 30-position automatic horizontal tool changer. Head in continuous rapid change. Spindle power 40 Kw. High pressure refrigerating system;

- Continuous AFD milling 105 runs X 2000 Y 1600;

- Binding machine 4 visualised runs 1000 x 400.

Mechanical carpentry

- Wire and electrode welding, MAG and TIG;

- Band saw cutter;

- Various equipment for machine assembly;

- Carpentry construction department for medium and large sizes.

Other

- CEMB balancing machine mod. ZB3000/TC/GV maximum diameter 1400 x 8000 mm;

- Painting workstation with aspirator wall;

- We perform finishing processes such as chroming, toothing, grinding and heat treatments, in partnership with specialised companies that have worked in close collaboration for years with our company.